By TE Connectivity 343

Wire and cable management refers to a set of practices and strategies for planning, installing, labeling, maintaining and managing wire and cable systems in a variety of buildings, facilities and systems. It covers all aspects from the wiring and installation of wires and cables to regular maintenance and upgrades to ensure the safe, reliable and efficient operation of wire and cable systems.

The primary goals of wire and cable management are to minimize risks, prevent failures, improve system performance, and ensure that electrical equipment within a facility is properly powered.

Ⅰ. The importance and purpose of wire and cable management

1. Safety: Wire and cable management helps reduce fire, electric shock and other safety risks. Proper routing, insulation and protection of wires and cables can prevent hazards caused by short circuits, overloads or damage.

2. Efficiency: Optimized wire and cable layout can improve energy efficiency and reduce energy waste. Proper cabling can also reduce resistance, voltage drops, and energy losses, thereby making the system more efficient.

3. Reliability: Good wire and cable management helps prevent failures and outages, thereby maintaining system reliability. Proper wiring planning and regular maintenance can reduce the risk of aging, damage and loosening of wires and cables.

4. Manageability: When there are a large number of wires and cables in the system, effective management can reduce confusion and errors. Clear identification and classification make it easier for people to identify and understand different wires and cables.

5. Easy maintenance: Good wire and cable management includes clear identification and documentation, allowing maintenance personnel to quickly locate and solve problems. This helps reduce maintenance time and downtime.

6. Compliance: Compliance requirements often include wire and cable safety standards and regulations. Proper wire and cable management helps meet regulations and standards and avoid fines and legal liability.Safety Issues in Wire and Cable Management

7. Prevent accidents: Intricate wire and cable layouts can lead to accidents such as tripping, falling, or becoming entangled in equipment. Proper management can reduce these potential hazards.

8. System integration: In modern facilities, many systems (such as power, communications, networks, etc.) require a large number of wires and cables. Effective wire and cable management helps ensure these systems integrate and work together smoothly.

Ⅱ. Network and data cable management

1. How to avoid interference and signal attenuation when laying out network and data cables

Keep your distance: Try to avoid placing data cables close to high-voltage lines such as power lines and lighting lines, as these lines may cause electromagnetic interference.

Eliminate ground loops: Avoid creating ground loops in the cable path, as this can cause interference signals to return.

Use shielded cables: For scenarios that require high anti-interference performance, using shielded cables can effectively block external interference signals.

Ground wire connection: For shielded cables, ensure that the ground wire of the shield layer is properly connected to provide effective shielding effect.

Correct routing: Try to avoid running data cables in parallel with other cables, especially high-voltage cables. Cross-arrangement or routing at 90-degree angles can help reduce interference.

Good Grounding: Ensure equipment and cables are well grounded to reduce electromagnetic interference.

Use a signal amplifier: When the signal transmission distance is long, a signal amplifier can be used to enhance the signal and reduce attenuation.

Proper Cable Length: Avoid using cables that are too long as the signal may be attenuated over long cables.

Maintenance and Inspection: Regularly check the connections and condition of your cables to make sure nothing is loose or damaged, which can reduce the risk of signal degradation.

2. How to ensure network performance

TIA/EIA-568 standards: This is a series of standards for communication cabling inside commercial buildings, covering cable types, connectors, wiring configurations, etc. The TIA/EIA-568 standard has multiple versions, such as 568A, 568B, etc.

Identification and Labeling: Clearly identify and label each cable and connector for quick identification and maintenance when needed.

Choose the right cable: Choose the cable type that suits your network needs, such as Cat5e, Cat6, Cat6a, etc., to support the required data rates and performance.

Regular testing: Regular testing of cables using test equipment to ensure their performance and the quality of their connections.

Zoned cabling: Dividing the network into different areas, each with a network access point, helps with management and troubleshooting.

Proper Bend Radius: Avoid bending cables excessively to reduce signal loss.

Cross-cabling: Use cross-cabling to connect networks on different floors or areas to a central cross-connect point to provide greater flexibility.

Distance Limitations: Make sure the transmission distance of the selected cable type does not exceed its stated limits to avoid signal attenuation.

Star Cabling: Centralizes all network connection points in a central location to simplify management and maintenance.

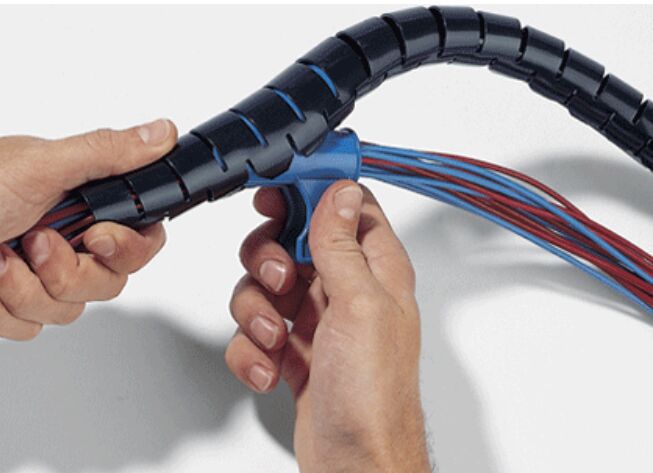

Patch panels and cable trays: Use patch panels and cable trays to organize cables and prevent them from getting tangled and damaged.

Fiber optic cabling: For scenarios that require high-speed, long-distance transmission, you can consider using fiber optic cabling to provide better performance and anti-interference capabilities.

Appropriate connectors: Use the appropriate connector type and make sure it is compatible with the selected cable to reduce signal attenuation.

Avoid electromagnetic interference: Avoid running data cables in parallel with high-voltage cables and use shielded cables and connectors to reduce interference.

Ⅲ. The relationship between wire and cable management and intelligent building, industrial automation and other fields

1. Industrial automation: In the field of industrial automation, a large number of wires and cables are used to connect various sensors, actuators, controllers and equipment. These wires and cables need to be routed according to strict standards to ensure stable communication and precise control between devices. Any wire and cable failure can lead to production interruptions, so wire and cable management is critical to maintaining productivity.

2. Smart buildings: In smart buildings, wire and cable management is critical to achieve automation, energy efficiency and user experience. Wire and cable wiring needs to meet the connection needs of various smart devices, sensors and systems, such as smart lighting, temperature control, security systems, etc. Good wire and cable management will ensure that these devices work properly and coordinate with each other, while also helping to quickly identify and troubleshoot problems.

3. Data center: The data center is a key component in the field of information technology, requiring a large number of wires and cables to support servers, network equipment and storage systems. Optimized wire and cable management can improve the flexibility, cooling efficiency and maintainability of the data center, ensuring the high performance and stability of the data center.Wire and Cable Management Applications

4. Energy management: In smart buildings and industrial environments, wire and cable management is also closely related to energy management. Proper wiring and cable layout and maintenance can reduce energy loss and waste and increase energy efficiency. In addition, wire and cable management can help monitor and control energy consumption for more sustainable energy use.

5. Internet of Things: The development of the Internet of Things requires a large number of sensors, devices and connections, all of which rely on wires and cables for communication and data transmission. Proper wire and cable management can support the interconnection of IoT devices, thereby realizing intelligent and automated application scenarios.

Ⅳ. Wire and cable troughs and channels

1. Function:

Organize and protect: Wire troughs and channels provide an orderly passage that can separate and neatly arrange different types of wires and cables, prevent entanglement and confusion between wires and cables, and reduce the risk of damage.

Maintenance and upgrades: By placing wires and cables in wireways and channels, maintenance personnel can more easily identify, inspect and maintain wires and cables without having to rummage through messy wiring.

Isolate interference: The isolation effect of the wireway and the channel can reduce the influence of electromagnetic interference and help maintain the signal integrity of the wire and cable.

Safety: Wire troughs and channels keep wires and cables in a safe place to prevent tripping and equipment damage.

Flexibility: When new wires and cables need to be added or upgraded, wireways and channels make it easier to add, replace or adjust.

2. Select the appropriate type and installation location:

Type Selection: Select the appropriate raceway type based on the number, type, and size of wires and cables required. Common types include metal raceways, plastic raceways, and cable ladders. Different types of wire ducts have different durability, protection and electromagnetic interference suppression capabilities.

Cable types: Different cable types may require different raceways, so consider the size, quantity, and type of cables when selecting raceways.

Installation location: The location for installing the wiring trough should be selected based on the wiring requirements and the layout of the equipment. Typically, wireways should be routed along walls, ceilings, or floors. The key is to ensure that the wiring ducts are located to facilitate maintenance and future expansion without affecting the normal operation of the equipment.

Ventilation and cooling: In environments that require cooling, such as data centers, pay attention to ventilation and cooling requirements when selecting raceways and channels to prevent overheating.

Environmental requirements: According to environmental conditions, choose cable ducts with corrosion resistance, dustproof, waterproof and other characteristics.

Ⅴ. Environmental factors considered in wire and cable management

Cable management is closely related to sustainable development. Considering environmental factors when managing wires and cables can help reduce resource waste and energy consumption, thereby promoting sustainable development.

1. Energy-saving design: In the design of wire and cable systems, energy-saving factors are considered, such as selecting equipment with higher energy efficiency, reducing energy consumption and cable length, etc., to reduce energy consumption.

2. Choose renewable materials: When purchasing cables, wiring ducts and other management equipment, give priority to the use of renewable materials or environmentally certified materials to reduce resource consumption and environmental impact.

3. Cable recycling: When replacing or upgrading cables, consider recycling and recycling old cables to reduce waste generation.

4. Cable selection: Choose cable types that meet energy efficiency standards, such as low-power, high-efficiency cables, to reduce energy consumption and carbon footprint.

5. Optimize wiring: Reasonably plan the wiring of wires and cables to reduce unnecessary length and waste. Avoiding excessive wiring can reduce resource consumption and energy waste.

6. Reduce carbon emissions: Through reasonable management of wires and cables, system failures and maintenance are reduced, thereby reducing maintenance vehicle travel and carbon emissions.

7. Energy efficiency: Optimize cable layout and connections to reduce energy loss and cable resistance and improve the efficiency of wire and cable systems.

8. Intelligent monitoring: Use intelligent monitoring systems to monitor the status of wires and cables, detect problems in time, and reduce unnecessary energy consumption.

9. Education and training: Provide environmental awareness education and training to employees and maintenance personnel so that they understand how to consider environmental factors in daily operations.

10. Environmental certification: Choose cables and equipment that meet environmental certification standards to ensure that they meet environmental requirements during manufacturing and use.

Ⅵ. The impact of aging of wires and cables on equipment and the environment

Performance degradation: Aged wires and cables can cause signal transmission quality to degrade, affecting the performance and operational stability of the device.

Safety hazards: Aged wires and cables can cause electrical failures, leading to fires, electric shocks and other safety issues.

Increased risk of failure: Aging wires and cables are prone to problems such as breakage, damage and short circuits, increasing the risk of equipment failure, which can lead to downtime and interruption of production.

Increased energy consumption: Aging of wires and cables may lead to increased resistance, resulting in increased energy consumption and affecting energy efficiency.

Environmental impact: Aging of wires and cables may cause the release of wire insulation materials, affecting environmental quality.

Ⅶ.Methods to extend the life of wires and cables

Correct installation: The correct installation and connection of wires and cables is the key to ensuring their life. Follow installation specifications and avoid excessive stretching, excessive bending, etc.

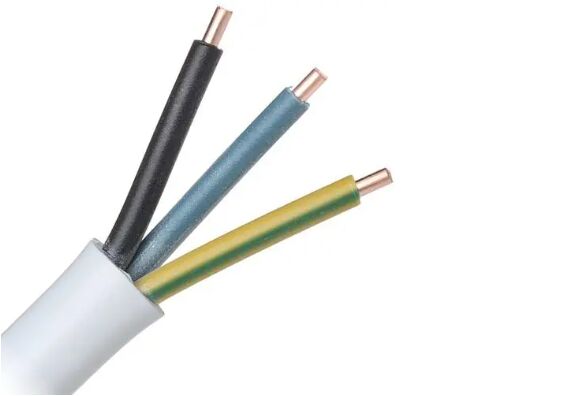

Choose high-quality materials: Choose high-quality wires and cables that meet standards, and the materials have good durability and can resist aging and environmental influences.

Environmental control: Try to avoid exposing wires and cables to extreme environmental conditions, such as high temperature, humidity, ultraviolet rays, etc.

Regular inspection: Regularly inspect the appearance and connection of wires and cables, looking for signs of cracks, deterioration, wear, etc.

Maintenance and upkeep: Perform regular maintenance and clean wires and cables to make sure there are no damages or loose parts.

Periodic testing: Use testing instruments to conduct periodic testing of wires and cables to check their electrical performance and transmission quality.

Protection measures: For vulnerable wires and cables, use protective sleeves, sheaths and conduits to protect them.

Preventive replacement: When wires and cables are nearing the end of their life, consider preventive replacement to avoid sudden failures.

Prevent overload: Avoid overload operation of wires and cables to reduce their load and extend their life.

Ⅷ.How to lay out cables to maintain signal quality and data transmission efficiency?

Avoid sources of interference: Try to avoid placing data cables close to equipment or power lines that may produce electromagnetic interference. This reduces the impact of interference on the signal.

Shielded cable: For situations where high anti-interference performance is required, choose to use shielded cable to block external interference signals.

Separate cable types: Separate cable types such as data cables and power cables. This helps prevent interference and signal loss.

Avoid parallel wiring: Try to avoid arranging data cables and power lines in parallel, because parallel wiring can easily cause mutual interference.

Use short distance connections: When possible, use shorter cable connections to reduce signal attenuation and interference.

Reduce connection points: Reduce the number of connection points and plugs in a cable to reduce the possibility of signal loss.

Use short distance connections: When possible, use shorter cable connections to reduce signal attenuation and interference.

High-quality cables: Choose high-quality, standard-compliant cables to ensure their transmission performance and anti-interference capabilities.

Shielded connector: Using a shielded connector can enhance the shielding effect of the signal and reduce external interference.

Signal amplifier: When the signal transmission distance is long, using a signal amplifier can enhance the signal and reduce attenuation.

Ground connection: Make sure the ground wire of the shielded cable is properly connected to provide better shielding effect.

Maintenance and Inspections: Regularly check cable connections and status to make sure there are no loose connections, damage, or other problems.

Frequently Asked Questions

1.What is wire and cable management?

Wire management, also known as cable management, is the use of specialized tools and equipment to control the direction or organization of wires or to protect the functionality of wires in an electrical system.

2.How do you troubleshoot a cable problem?

Unplug the modem's power cord. If a router is connected, unplug the router's power cord. Check for loose cables, including the coaxial cable and Ethernet cable. Plug back in the modem.

3.What are the best practices in wire and cable management in compliance with regulations and standards?

The TIA/EIA-568 standard series is an international standard for communication wiring in commercial buildings, including wiring systems, cable specifications, connectors and connection methods, etc. Choose the appropriate cable type and wiring method according to different versions of standards; ISO has issued multiple standards related to wire and cable management, such as ISO 18010 and ISO/IEC 14763-2. These standards provide guidance on an international scale.