By TE Connectivity 301

In the industrial field, wire and cable management is very important, it involves the layout, installation, maintenance and safety of electrical equipment. The effective implementation of wire and cable management can ensure the stable operation of the electrical system, prevent wire and cable damage, short circuit, fire and other safety risks, and improve production efficiency and equipment reliability.

Ⅰ. Application of wire and cable management in the industrial field

1. Wiring planning and design: In industrial facilities, various electrical equipment, control systems, lighting, etc. need to be connected, so wiring planning and design is required to determine the cable path, length and connection method to ensure the reliability of signal transmission and security. Industrial facilities often have a wide variety of electrical equipment, including control panels, motors, sensors, and more. Cabling planning requires determining the best cable routing to reduce interference and crossovers and ensuring proper cable lengths. The design process also needs to consider the type, cross-section and insulation level of the cable to suit the power requirements of different devices.Wire & Cable Management

2. Cable protection: In harsh industrial environments, cables are vulnerable to mechanical damage, chemical corrosion, oil pollution, etc. The use of cable protection sleeves, jackets and isolation materials can prevent damage to the cable from external elements and prolong the service life of the cable.

3. Cable channels and bracket systems: cable channels, cable troughs and bracket systems are used to install and support cables so that they can be arranged in plants or equipment in an orderly manner. This helps avoid cable tangling, making maintenance and troubleshooting easier. Cable channels, cable trays and bracket systems to securely mount cables on walls, ceilings or floors without cable clutter.

4. Joint and connection management: Industrial equipment often requires frequent maintenance and replacement, which may involve the removal and reconnection of cable connections. Good splice and connection management ensures reliable connections and reduces breakdowns during maintenance. The connection points of wires and cables are prone to failure, so good splice and connection management is required to ensure that the connection is strong and reliable, and to prevent signal interference and disconnection.

5. Maintenance and overhaul: Regular wire and cable maintenance and overhaul is the key to ensuring the continuity of industrial production. This includes cleaning cables, tightening connections, replacing aging cables, etc. Maintenance programs should be carried out without affecting production. Regular wire and cable maintenance and overhaul is an important step to ensure the continuity of industrial production. This includes cleaning, tightening, replacing cables, and checking for potential failure points.

6. Identification and marking: Proper identification and marking of wire and cable is the key to maintenance and troubleshooting. Marking can include information such as cable usage, connection port, voltage, etc. This helps to quickly and accurately locate specific cables when maintenance or connection changes are required. Proper identification and labeling of wires and cables can help quickly identify each cable's purpose, function and connection details. This is critical for maintenance, repair and troubleshooting.

7. Automation system: In modern industry, automation system uses a large number of sensors, controllers and actuators, which require a large number of cables to connect. Effective wire and cable management is critical to the stable operation of automation systems.

8. Ground treatment: In some industrial environments, there may be problems such as static electricity and electromagnetic interference on the ground, which may cause damage to cables and equipment. Proper ground treatment can alleviate these problems and ensure the stability of signal transmission.

9. Data center management: Cable management is particularly important in industrial fields that require a large amount of data transmission and connection, such as data centers, manufacturing, etc. Not only power cables need to be managed, but also network and communication cables.

10. Safety management: Reasonable wire and cable management can reduce the probability of fire, electric shock and other electrical safety risks. In an industrial environment, safety is always paramount, and proper management of wires and cables can help reduce the risk of accidents. In industrial environments, poor management of wires and cables may lead to safety issues such as fire and electric shock. Therefore, cable management needs to follow safety standards and regulations to ensure that the cable layout complies with safety requirements.

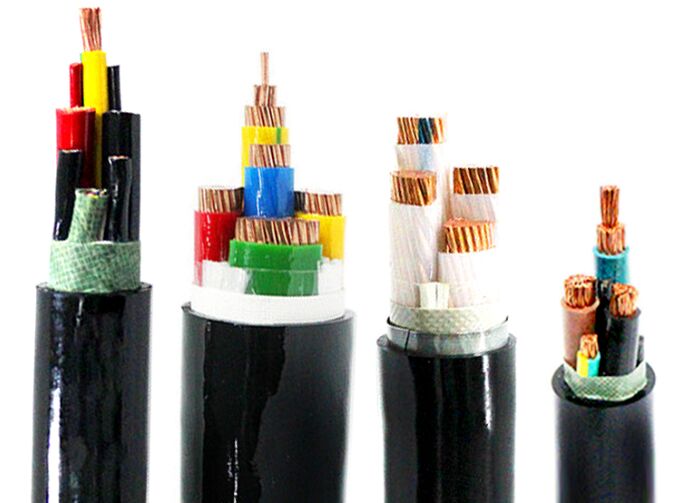

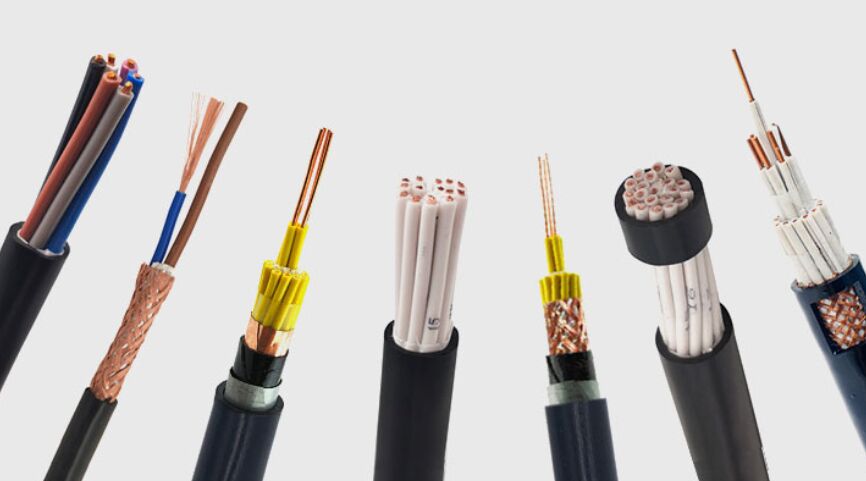

Ⅱ. Classification and identification of wires and cables

1. Classify and identify wires and cables according to their usage, voltage and other characteristics:

Choose a method of identification: The method of identification can be color coding, symbols, labels, etc. Choose a method that is clear and concise to ensure easy legibility.

Use classification: Classify wires and cables according to their uses, such as power transmission, control signals, communication data, etc. Cables for different purposes may need to withstand different loads and environments.

Color coding: Color coding is one of the commonly used wire and cable identification methods. Different colors represent different properties. For example, in the United States, cables used for AC power transmission may be color coded as follows:

Black: Hot wire

Green or green and yellow: Ground wire

White or gray: Neutral wire

Determine the classification standard: It is necessary to determine the classification standard for wires and cables. This can be based on usage, voltage, current, environmental conditions, etc.

Voltage level classification: Classify according to the voltage level of the wire and cable. Generally, wires and cables are classified by low-voltage, medium-voltage and high-voltage grades.

Labels and Identification Plates: Labels or identification plates are used to attach wires and cables with words, icons or symbols for cable information. This can include usage, voltage, current capacity, etc.

Compliance with standards: When classifying and marking wires and cables, ensure that you follow national or industry standards and regulations. Different regions have different color coding and identification requirements.

Digital coding: It is also an effective method to use digital coding to identify wires and cables. Each number can represent a different characteristic, such as cable type, cross-section, voltage class, etc.

Database management: For large industrial facilities or complex wire and cable networks, it is also a good method to establish a cable information database. This can contain detailed information for each cable for easy query and management.

Graphical symbols: It is also a way to use specific graphic symbols to represent the characteristics of wires and cables. This is useful for those situations where you need to quickly identify the purpose of the cable.

2. Methods to effectively identify different types of wires and cables:

Area Separation: Install different types of wires and cables in separate areas to reduce confusion and crossover. This can be done with cable channels, slots or brackets.

Combination of identification methods: Multiple identification methods can be used in combination, such as color coding plus number coding, to provide more comprehensive and clear information.

Data management system: establish a cable information database to record the detailed information of each wire and cable. This can include cable type, usage, specification, date of installation, etc. This method is suitable for large and complex cable networks.

Ⅲ. Arrangement and orientation of wires and cables

1. Arrange the path

First, understand the requirements of the electrical system, including the devices that need to be connected, control systems, sensors, etc. Learn about the location and function of each piece of equipment, as well as possible future expansion plans.

Divide industrial facilities into different areas and levels, and place related wires and cables in the same area according to the use and voltage level of the cables.

Try to choose the shortest path of wires and cables to reduce cable length and loss. This helps to increase the efficiency of the electrical system and reduce energy consumption.

Organize wires and cables on walls, ceilings or floors with cable channels, troughs and bracket systems. This helps avoid cable clutter and facilitates maintenance.

Avoid placing wires and cables close to interference sources (such as strong power sources, electromagnetic interference sources) to reduce signal interference and safety risks.

When arranging paths, you can consider designing backup paths so that when the main path fails, it can switch quickly and reduce downtime.

Use signs and records on routing paths to quickly identify the purpose and connection of each wire and cable. This is very useful for maintenance and extension.

When planning the routing of wires and cables, be sure to follow applicable electrical standards and codes. This ensures security and compliance.

Some electrical design and wiring software tools can help simulate and plan the layout path of wires and cables, and optimize the wiring scheme.

2. Layout strategies for different places

office:

Cable Management: Use cable managers and troughs to organize wires and cables and avoid crossing and tangles. This helps keep the office clean and safe.

Office equipment layout: According to the equipment layout of the office, arrange the wires and cables in a position close to the equipment and without hindering traffic. Keeping the wires and cables on your desk tidy and organized will help you work more efficiently.

Data Communications: Offices often require a large number of data communication cables, such as network lines and telephone lines. These cables need to be connected properly to ensure communication stability.

Future Expansion: Considering possible future expansion of the office, some additional cable paths should be reserved for wiring.

family:

Safety First: In the home, safety is the number one consideration. Wires and cables should be placed where they are not easily touched or tripped over to prevent electric shock and accidents.

Wiring Channels: Decorative cable channels or troughs can be used to safely hide wires and cables from tripping and clutter.

Appearance considerations: The layout of wires and cables in the home should also consider the appearance. Wires and cables can be hidden behind walls, floors or furniture to keep the room tidy and beautiful.

Flexibility: Considering that the layout of the home may change, the wiring should have some flexibility so that adjustments can be made when needed.

Industrial facilities:

Durability: In industrial facilities, wires and cables may be subject to mechanical damage, chemical corrosion, etc. Therefore, wires and cables should use durable materials and require appropriate protection measures.

Safety: Wire and cable arrangements in industrial facilities need to meet strict safety standards to prevent fire, electric shock and other potential risks.

Cable channels and brackets: Since industrial facilities often have complex electrical systems, cable channels, troughs and bracket systems can be used to install wires and cables in an orderly manner on equipment and structures.

Automation needs: In the automation industry, there are many sensors, controllers and actuators that need to be connected. The wire and cable layout needs to be adapted to the needs of the automation system.

Identification and Documentation: In an industrial environment, where wires and cables can be more complex, identification and documentation becomes even more important. The purpose, connection and specification of each cable needs to be clearly identified.

Ⅳ. Importance and challenges of wire and cable management

1. Importance

Wire and cable management is critical to preventing fire, electric shock, and other safety incidents. Proper cable routing can reduce the risk of cable damage, short circuits and leakage, ensuring the safety of workers and equipment. Good wire and cable management can ensure the stable operation of the electrical system. Messed-up cables or incorrect connections can lead to equipment failure, downtime and lost production.Wire & Cable Management organizer

Clear wire and cable layout and identification can improve the efficiency of maintenance and repair. Staff can quickly identify fault points, reducing maintenance time. Good wire and cable management can reduce wiring complexity and save time and money when future equipment expansions or upgrades are required.

Effective wire and cable management saves money by reducing cable damage and maintenance expenses, reducing energy waste and the risk of production downtime. Proper wire and cable management can ensure compliance with electrical safety standards and regulations and avoid potential legal issues and fines.

2. Challenge

Different environmental conditions may cause damage to wires and cables, such as humidity, temperature changes, chemical substances, etc. Wire and cable need to adapt to various environmental requirements. If wires and cables are not properly identified and documented, it can be difficult for maintenance personnel to locate and fix problems, resulting in inefficient maintenance.

In large industrial facilities, wire and cable arrangements can be very complex, involving multiple uses, voltage levels and connections. Managing and maintaining such a cable network can be challenging. Poor wire and cable management can lead to fire, electric shock and other safety risks, posing a threat to personnel and equipment.

Ⅴ. Wire and cable management and green sustainable development

1. Reduced environmental impact:

Reduce energy consumption: Optimized wire and cable layout can reduce energy demand, reduce the load on the power supply system, and help reduce the use of fossil fuels and carbon emissions.

Prevent pollution: Good wire and cable management can avoid cable damage, fraying or leakage, and reduce the risk of contamination of soil and water sources.

2. Resource and energy efficiency:

Reduce material waste: Reasonable wire and cable layout can reduce the length of cables, thereby reducing the amount of materials used and resource consumption.

Save energy: Good wire and cable management can reduce energy waste. The layout and connection of wires and cables should be optimized to reduce resistance and energy loss.

3. Life cycle management:

Sustainable maintenance: Good wire and cable management can prolong the service life of wires and cables, reduce the frequency of maintenance and replacement, and reduce waste generation.

Future expansion: Consider future expansion requirements when planning the layout of wires and cables, avoid frequent replacement of wires and cables, and reduce resource consumption.

4. Health and safety:

Reduce the risk of electric shock: Reasonable wire and cable layout can reduce the chance of people touching wires and cables and reduce the risk of electric shock.

Fire prevention: Good wire and cable management can reduce problems such as overloading and short-circuiting of wires and cables, thereby reducing the risk of fire and protecting people and the environment.

5. Sustainable management methods:

Regular inspection and maintenance: Regular inspection of the condition of wires and cables and timely maintenance can reduce the aging and damage of wires and cables and prolong their service life.

Sustainable material selection: choose environmentally friendly materials to manufacture wires and cables, such as recyclable materials and low-pollution materials, to reduce resource extraction and environmental load.

6. Ways to reduce wire and cable waste:

Before you start wiring, do careful planning to make sure each wire and cable is the right length. Avoid excessively long cables, thereby reducing material waste. In industrial facilities or buildings, modular design can reduce the use of wires and cables. The modular design avoids redundant cables because only what is needed is connected. When planning the wire and cable layout, reserve some extra cable paths to accommodate possible future equipment expansion and upgrades. This avoids frequent replacement of wires and cables.

Ⅵ. Line and cable management case

1. Medical facilities: Medical facilities require highly accurate and stable electrical systems. Successful wire and cable management examples involve routing wires and cables around medical equipment, ensuring that wires and cables do not interfere with medical operations, while maintaining the safety and accuracy of the system.

2. Industrial automation projects: Many large-scale industrial automation projects have successfully implemented efficient wire and cable management. By using digital tools and software, they are able to plan and optimize wire and cable layouts, improving equipment stability and maintainability.

3. Energy engineering: In energy engineering, wire and cable management is crucial for power transmission and distribution. In successful cases, wires and cables are placed in proper locations to reduce energy loss and equipment failure.

4. Construction projects: In large-scale construction projects, reasonable wire and cable management can improve the safety and efficiency of the building. In some cases, wires and cables are embedded in walls or floors to keep the appearance clean and the space usable.

5. Lessons learned:

Regular maintenance and inspection: Maintenance and inspection are the key to ensure the stability of the wire and cable system. Regularly check the status of wires and cables, and find and solve problems in time, which can prolong the life of the system.

The importance of planning: Proper wire and cable management requires careful planning and design. Before the project starts, it is necessary to fully understand the requirements and constraints, and develop an effective wiring scheme.

Use digital tools: Cable management software and digital tools can help optimize cabling and reduce waste and errors. These tools can provide more precise wiring paths and connections.

Continuous Improvement: Organizations in success stories often engage in continuous improvement, finding more efficient ways to manage wire and cable. Cabling plans are regularly reviewed and improved to accommodate changing needs and technologies.

Frequently Asked Question

1.What is wire and cable management?

Wire management, also known as cable management, is the use of specialized tools and equipment to control the direction or organization of wires or to protect the functionality of wires in an electrical system.

2.Why is it important to manage wire and cable?

Cable management is essential to create a visually pleasing and clean work environment. Managing cables or wires help maintain basic functionality and protects the devices from the clogged airflow due to messy and disorganized cables. Tangled wires or cables are generally frustrating and time-consuming to untangle .

3.How to deal with the influence of humidity, temperature and other environmental factors on wire and cable?

In places with harsh environmental conditions, it is very important to choose wire and cable materials that are resistant to moisture, temperature and corrosion. Make sure to select materials that meet the needs of your specific environment. In high temperature environment, ensure that the wires and cables have adequate ventilation and cooling to prevent overheating. Consider using a heat sink or fan to maintain proper temperatures.